|

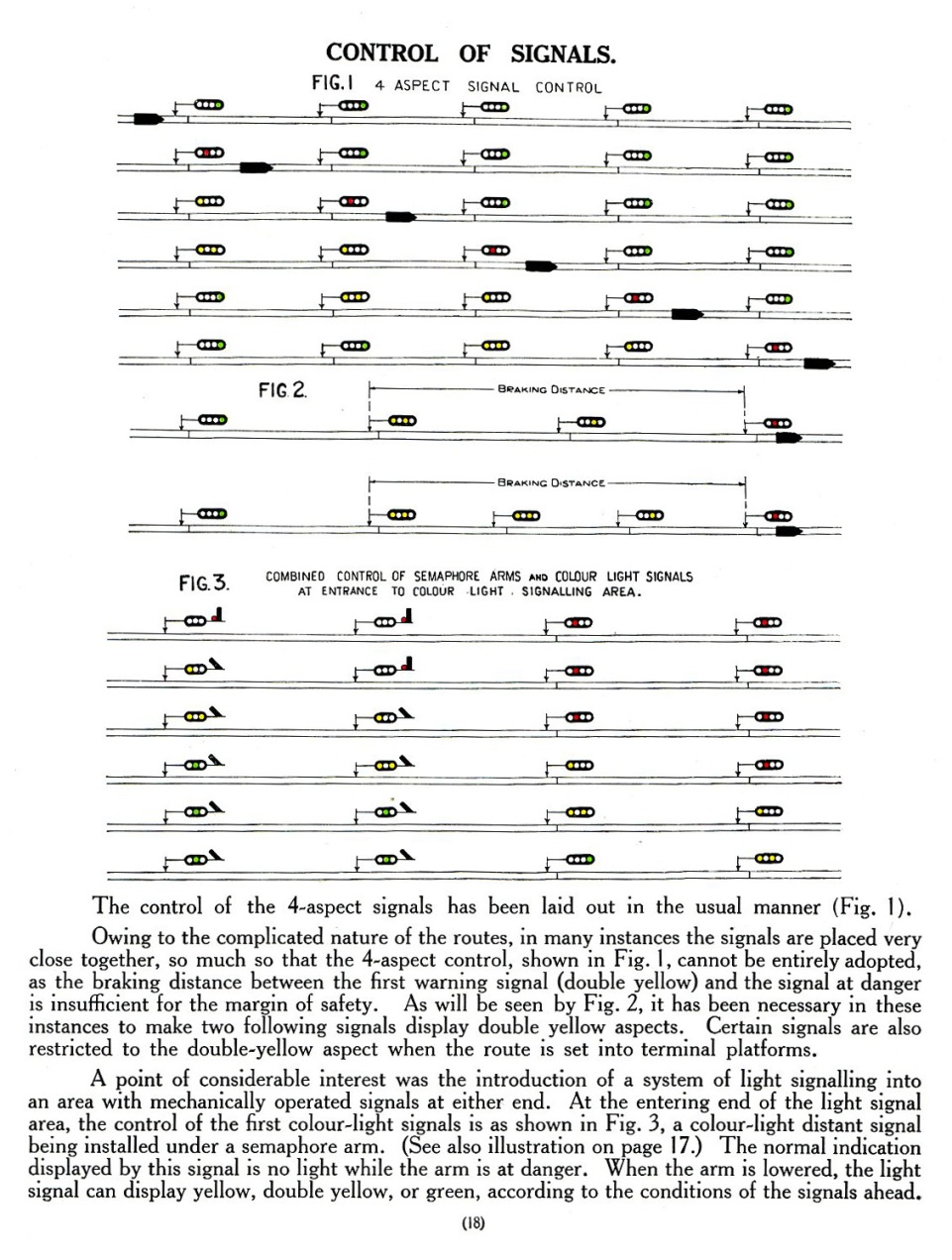

|

The advantage of the letting of a contract to a large signalling firm, with its

drawing office, workshops, staff of engineers, erectors, etc., is that the work

can progress in an orderly and systematic fashion. This avoids the confusion which

must occur when material ordered by a Railway Company arrives either before or after

the date on which it is required. Immediately the notification is given of the acceptance

of a tender, it is possible to notify works to proceed with the preparation of the

material; and the instructions are given in such order that the flow of material

to the site is in the sequence required by the construction staff. This avoids the

necessity for storage of a considerable quantity of material on the ground, with

double handling, risk of damage, fire, etc., it being possible to deliver the bulk

of the material directly on the site at which it has to be fixed. For instance,

on the Manchester installation it was possible to start work on the interlocking

frames almost immediately the order was received, and to commence their erection

in readiness for the locking, which was designed by the Railway Company's engineers

and forwarded later. Signals, point machines, relays, and other details could also

be put in hand. In the meantime, meetings between the Contractors and the Railway

Officials were arranged on the site for the purpose of settling details. These included

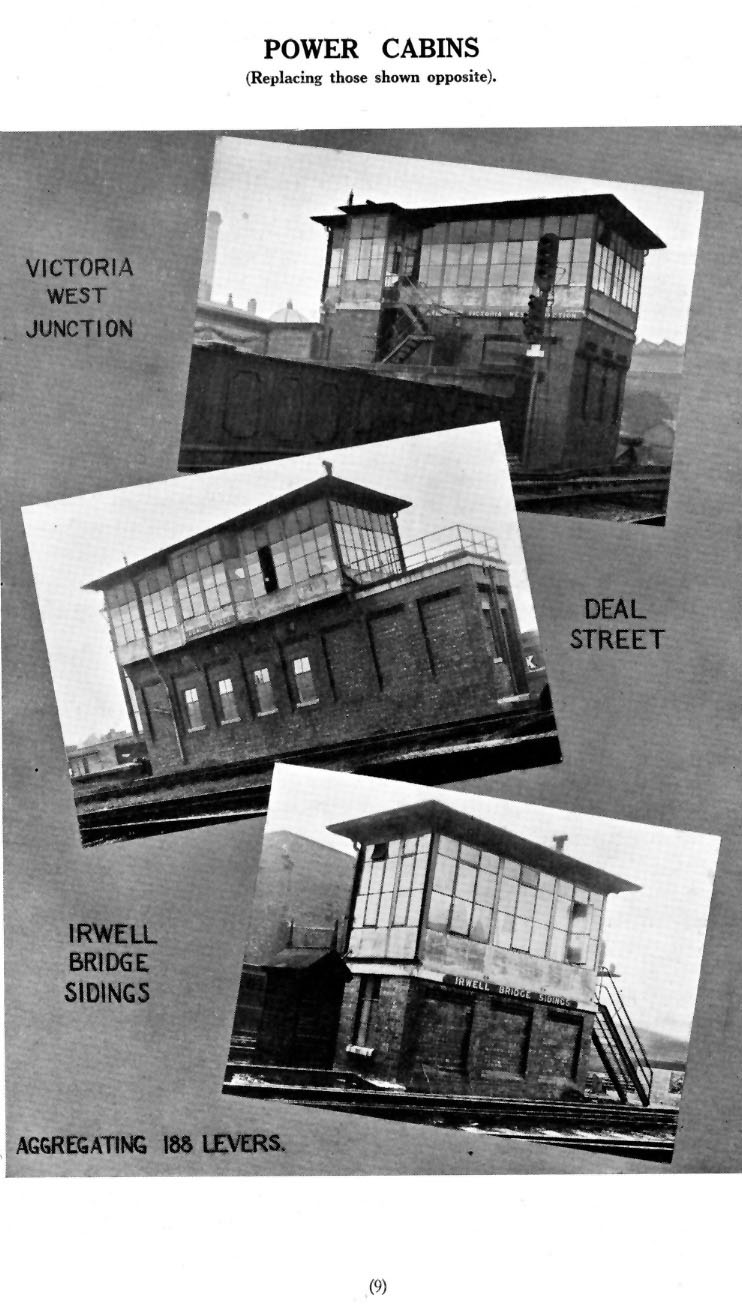

the design of the signal cabins, which was in itself a difficult problem, owing

to the very limited space available, the line being mainly built on viaducts. The

photographs on page 9 show the neat way in which these have been arranged.

At the early meetings a problem of some difficulty had to be tackled — i.e., so

to design the ground connections for the power point layouts that they would be

adaptable to the varied types of switches and other permanent way existing on the

site. It should be remembered that two main types of permanent way — namely, L.

& Y. and L. & N. W. — already existed, while new work put in was to revised

British Standard, and it was well known that all replacements in future would be

of the latter type. While it was not possible to make every detail adaptable to

the varying types, as each railway had used from time to time different patterns

of switches, chairs, tie-plates, etc., a design was finally arrived at to connect

to the R.B.S. type of permanent way, without the necessity of drilling any holes

on the site, and yet which could be fitted to the old L. & Y. and L. & N.

W. switch layouts with only minor alterations. Thus, in the event of these layouts

being converted at any time to the British Standard, the apparatus supplied will

be suitable. The photographs on pages 19 to 21 show the neat and simple design of

this layout. This is of importance to the Railway Companies, not only because of

the first cost of installation, but also because of the small amount of labour involved

when renewals are necessary, such renewals generally calling of overtime on the

part of the Signal Department's forces. As an illustration of the ease with which

these layouts can be installed, the Contractors were able, without the necessity

of bringing extra staff to the work, to fit and bring into operation some 50 pairs

of points in one night.

Meetings on the ground also determined the exact positions in which the signals

were to be fixed, the Contractors providing templates and foundation bolts. The

Railway Company was enabled to have the latter set in readiness for the arrival

of the signals. Many of the foundations were pre-cast, and thus the necessity of

hauling ballast, cement, and water to the site was avoided. It was not possible

to do this in every instance, because in some cases walls, arches, and piers had

to be interfered with.

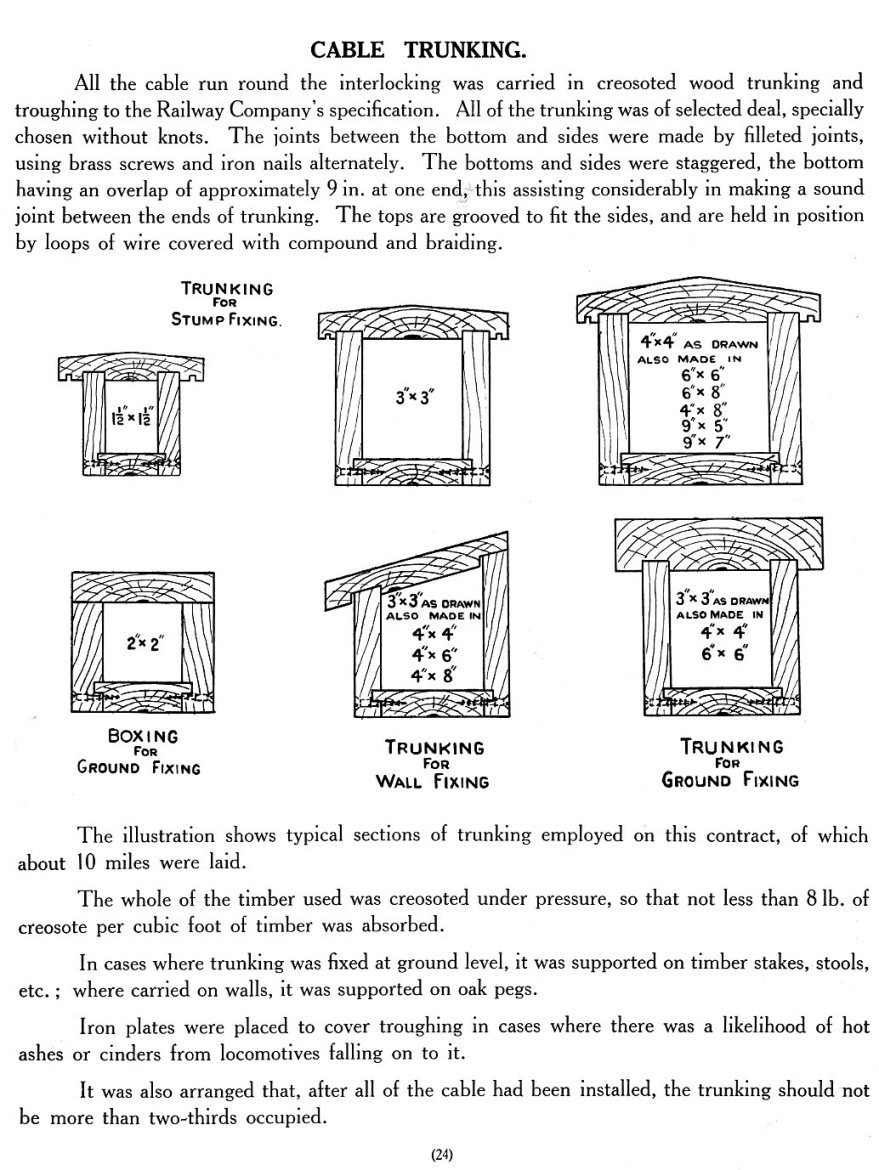

A matter of considerable difficulty in railways built on viaducts and arches of

this character is the installation of cables. The Contractors prepared plans showing

the cables required to be run, and their routes ; and calculated the sizes of the

trunking, etc.; and, directly the approval of the Railway Company was given, were

able to commence the installation. Co-operation between the Railway Officials and

the Contractors resulted in the preparation of designs of the most economical sizes

in view of standard timber available (see page 24). In certain instances, where

large runs of cable had to cross under tracks (see page 27), it was decided to instal

fibre conduit in concrete with manholes at intervals. The conduit, manhole covers,

and rims were supplied by the Contractors and installed to their drawings by the

railway staff.

In order that a clear understanding of the magnitude of this undertaking can be

obtained, a plan has been prepared, the upper portion of which shows the permanent

way and signals as they existed prior to the alterations, the lower the completed

work. This is inserted opposite page 28.

Crossover junctions have been laid in between the Slow South Lines and the Slow

North Lines, and corresponding junctions between the Slow North Lines and the Slow

South Lines. An advantage of these arrangements is that, whilst the North Lines

continue to command all the platform lines in Victoria, they are also connected

with all those in Exchange. Similarly, in addition to the South Lines having access

to all the platforms in Exchange, they also serve all those in Victoria. As a consequence,

trains can now leave Victoria for destinations served by the South Lines — e.g.,

North Wales, — and can depart from Exchange for all places in the North and West

for which Victoria only was generally used. This is a great public convenience,

as it saves many passengers having to transfer between the two stations.

It is now possible to close Exchange Station entirely, if desired — as, for instance,

on Sundays.

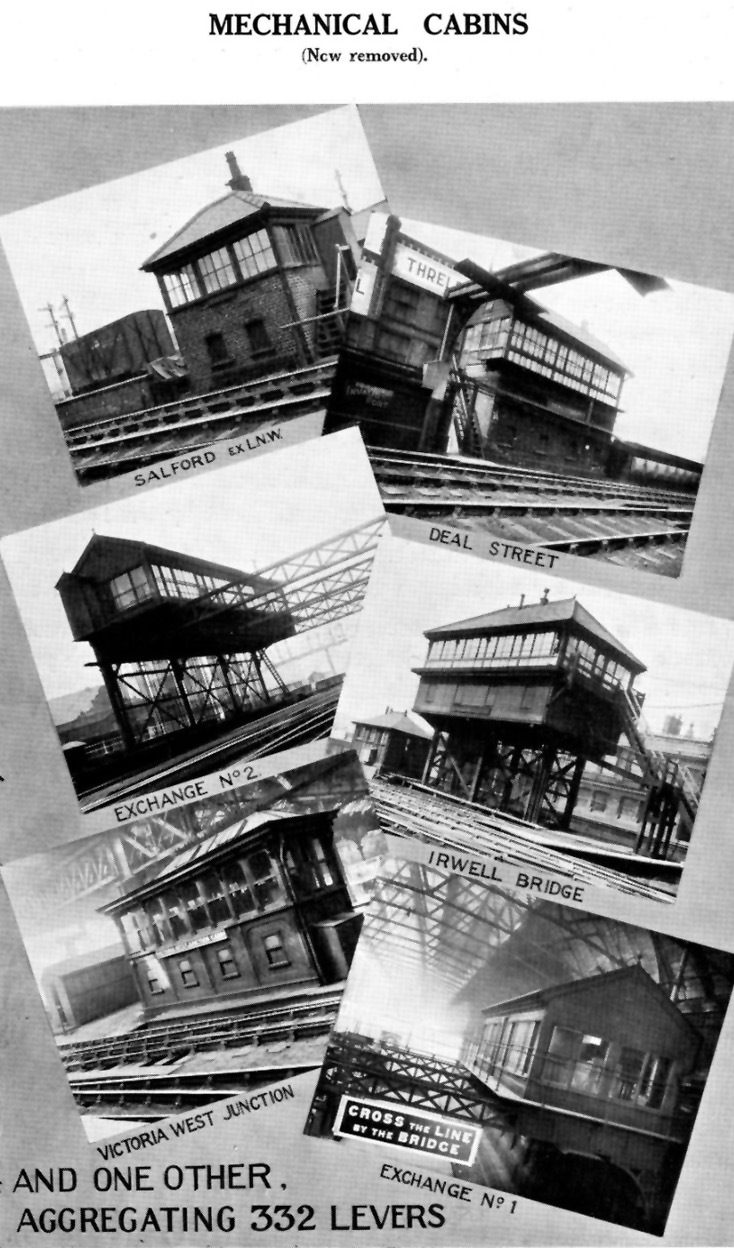

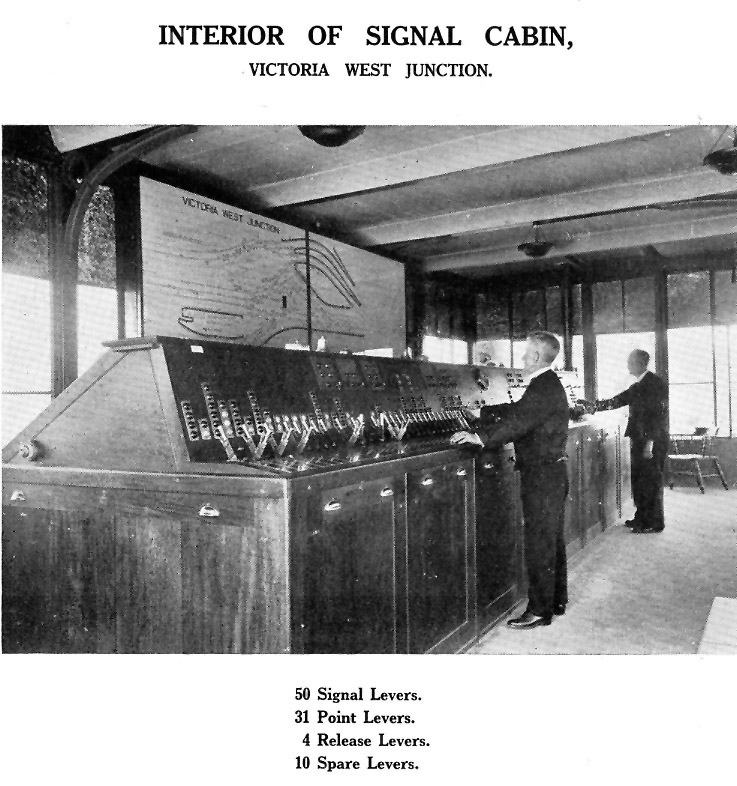

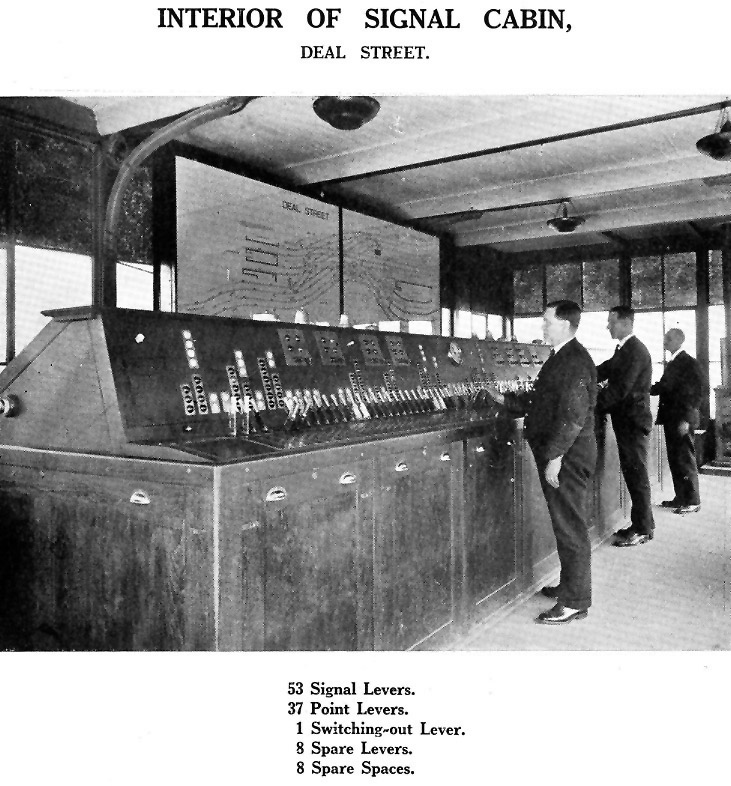

The signal cabins are shown on both of these plans. Originally there were ten, with

a total of 589 levers, whereas in the final scheme there are three power-worked

cabins—Deal Street, Victoria West Junction, and Irwell Bridge Sidings, — and three

mechanical boxes — Ordsall Lane, Salford, and Victoria East Junction. From these

last a considerable number of mechanical levers have been removed, and the totals

are now 188 power levers and 216 mechanical for the whole of the section shown on

the plan. There is thus a saving of four signal cabins and 185 levers, notwithstanding

which there are a considerably greater number of points and signals to be controlled

than in the original scheme.

There has been effected altogether a saving in operating staff required of 11 signalmen,

and it will be also appreciated that the communication between the shunters, platform

staff, and other traffic officials with the signal cabin has been much simplified.

Of course, it could have been arranged for all the power working to be operated

from one central cabin, but a careful study of the conditions at Manchester showed

that there are two main divisions of work, made necessary by the varied nature of

the traffic which has to be dealt with. One of the chief characteristics of Victoria

and Exchange Stations is that many local passenger trains start and terminate at

one or other of them, requiring considerable marshalling just outside. Again, at

certain times many classes of trains — other than through traffic — have to be speedily

handled, also necessitating local communication between the shunters and the signal

cabin.

For these, and other relatively minor, reasons, it was deemed advisable to divide

the signalling also into two main areas, each with its own cabin, from which all

local movements could be regulated, but with interccmmunication for through traffic.

A feature of some interest with the new arrangement is that at night time and on

Sundays there is now no necessity to cross over trains from their ordinary running

lines at Deal Street Signal Cabin. Arrangements have been made whereby, when the

points are set for the straight lines and the signal levers reversed, the pulling

of a switch-out lever converts the straight road signals on the North Lines into

automatic working, with a consequent saving in operating staff.

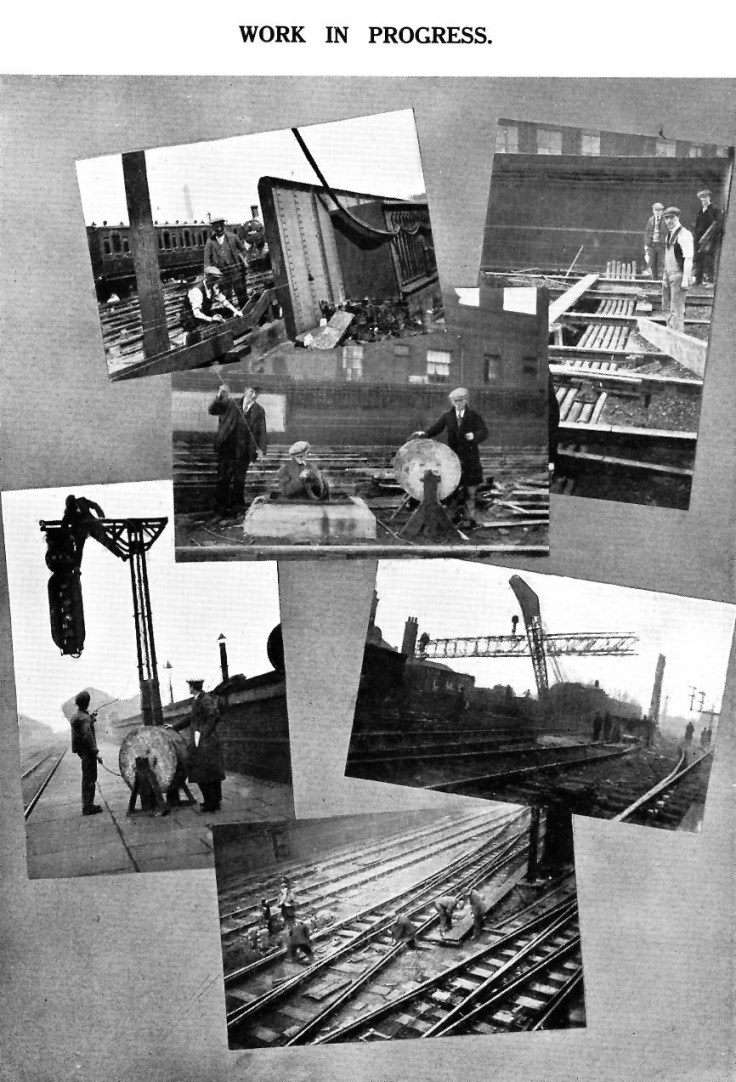

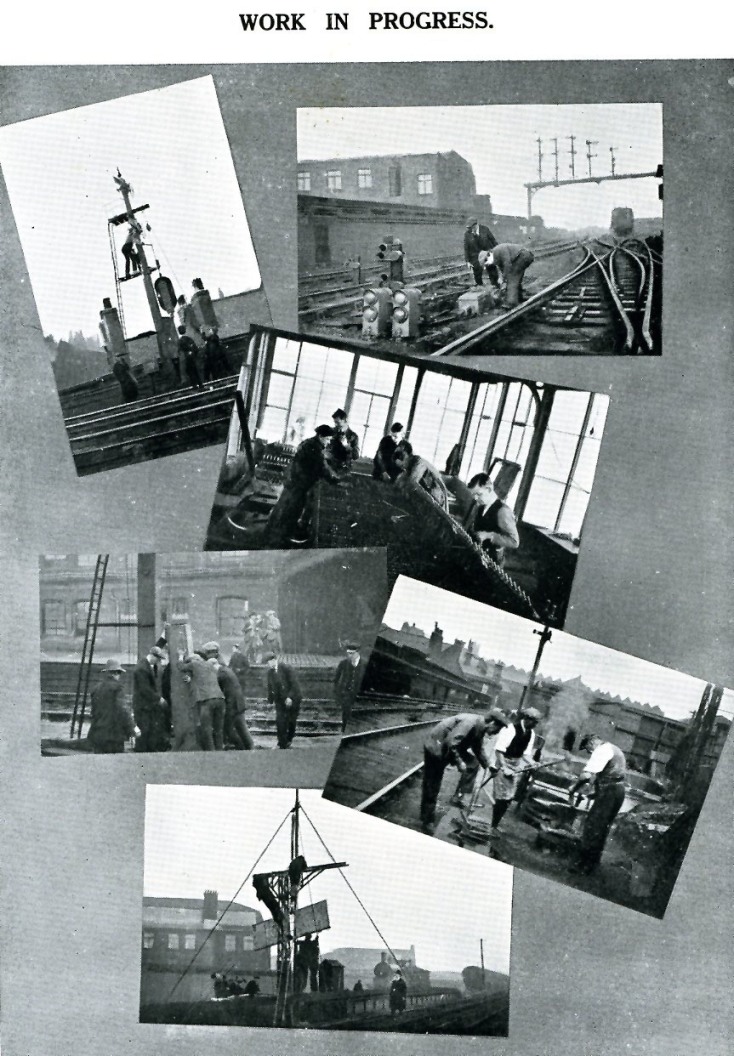

The work was carried out in approximately the following order : —

(a) Installation of trunking and bonding of rails carried out simultaneously. At about this time the Railway Company commenced setting the foundations for the signals, and the building of the signal cabins.

(b) Delivery of signal posts commenced, and these were erected on arrival ; cable was run in the trunking already fixed.

(c) Point machines were received and fixed as and when the timbers on which they were to be fixed were installed by the Railway Company.

Trunking for the track connections was installed, and the wiring to the rails, as well as the jumpers, laid and connected up. At the same time the Railway Company installed the insulating rail joints.

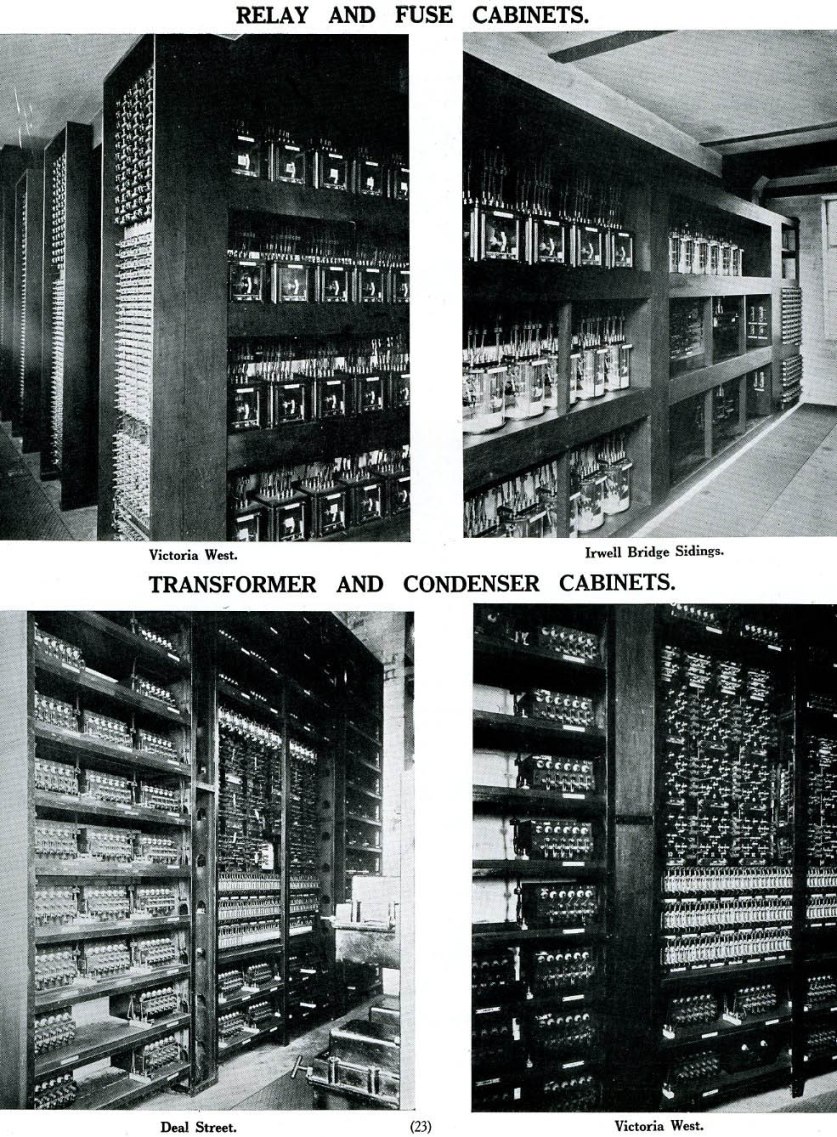

(d) As soon as the signal cabins were ready, the power frames were delivered and erected, the locking installed and tested, and the teak cabinets for relays, transformers, and fuse housings, which were manufactured in the Contractors' works, were delivered to the site and erected. Relays and transformers had by this time arrived on the site and were installed in these cabins, and the work of wiring-up commenced.

(e) The installation of apparatus and the wiring up of all the outside fittings

progressed continuously in such order as to allow the Contractors, soon after current

was available, to commence testing individual pieces of apparatus, and afterwards

to make exhaustive tests of the whole of the work prior to the completion of the

Railway Company's own tests. These latter were carried out in sufficient time to

enable the installation to be brought into service in time for the Easter

holidays, when heavy traffic is always experienced

at

After many consultations

between traffic and engineering officials, it was decided that the new system of

signalling should be brought into service in three sections, and on dates as near

together as possible (successive week-ends), without interfering unduly with the

traffic.

The first stage comprised

the new signalling on the old L. & Y. section — that is, from Salford to

The whole of the work was

carried out by the Contractors with the exception of minor details of preparing

the foundations for signals and gantries, cutting away of brickwork, etc., which,

in view of the construction of the line, was better carried out by the Railway Company.

The signal boxes, though

built to suit the Contractors' apparatus, were designed by the Railway Company and

erected by a local firm under the supervision of the Resident Engineer.

It is very interesting to

note the neatness of the whole of the construction work and the absence from the

track of point rods, signal detectors, etc. —obstacles which previously prevented

easy walking thereon. This is of considerable advantage to the staff whose duties

necessitate their presence on the lines.

The maintenance work is undertaken

in three shifts, and requires only one linesman to be on duty at one time.

Installation in Service

The organisation agreed upon

between the Railway Officials and the Contractors was successful in that all work

was completed to schedule time. The specification called for the work to be carried

out in not more than fifteen months. The contract was let in November, 1927, and

the final opening took place in March, 1929, despite the severity of the weather

conditions during the installation period. It is perhaps worthy of mentioning that

the only delays which occurred subsequent to the change-over were attributable partly

to the bad fogs experienced during that period, and partly to the difficulty the

operating staff had in becoming conversant with the new conditions. This difficulty

will be appreciated when it is understood that some thousands of drivers and other

men from all parts of the country had to be conducted round the site before the

new signals were brought into service, the traffic which enters

Since its installation, the

system has operated exceedingly satisfactorily, and under the most severe conditions.

Trains are arriving and departing with promptitude, drivers finding that the visibility

of the signals under all conditions, and the indications they display, enable them

to run with much greater confidence than in the past.

Electric Locking

All the most modern features

of electric locking have been employed, this being made possible by the use of complete

track circuits throughout the area concerned.

FIRSTLY—An illuminated diagram is

provided in each of the main cabins, immediately informing the signalman of the

position of any train under his control.

SECONDLY—All main signals are directly

controlled by the track circuits over which they read, as well as constantly detected

through all facing points on the route.

THIRDLY—By the use of approach and

back locking of point levers, the route over which any signal reads is held during

the passage of the train.

LASTLY—To provide maximum traffic

facilities, sectional release locking has been employed. As is well known, this

enables a fresh route to be set up at the earliest possible moment, only the points

ahead of the train being held, while those in the rear become free immediately after

the passage of the train. This special feature was adopted at

Many of the signals are approached

locked, and automatic time releases are provided in many instances to give maximum

traffic facilities without impairing the safety of the system.

Lever Arrangements.

In this installation there

are 192 signals (exclusive of distant signals) reading over 299 different routes,

which are controlled from 135 levers. The economy in signal levers has been accomplished

by means of signal selection and the use of " push-pull " levers for many shunt

signals, this being in accordance with the usual practice of the L. M. & S.

Railway for power installations. The normal position of the "push-pull" lever is

in the centre of the lever quadrant, the two reverse positions being " push " and

" pull."

All aspects of signals and

route indicators, as well as the positions "normal " and

reverse of points, are repeated above the corresponding levers

by illuminated indications let into the front of the interlocking frame.

The circuit generally employed

for signal indication purposes is the well-known series resistance " scheme, as

originated by the Westinghouse Company, the special feature being the constant indication

of any signal at any time without employing any apparatus having moving parts, the

indications in the cabin being proportional to the brilliance of the light displayed

by the signal itself.

Block Working.

Owing to the nature of the

traffic and the complicated routing of the trains at

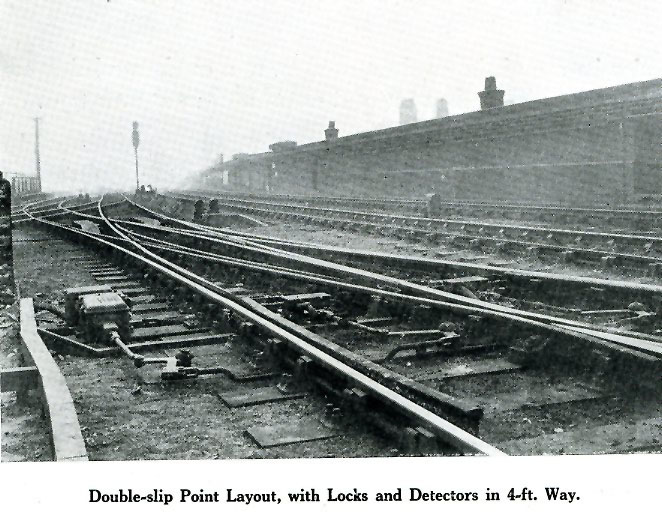

There are 137 point layouts controlled by 130 point machines. These are the Westinghouse

style M, and combine lock and detector in one unit. In a number of cases, such as

double slips or complicated routes, it has been necessary to fit locks and detectors

in the 4-foot way, using our standard style C point and lock detector. Constant

detection of all points is provided by using 3-position A.C. Vane Point Detection

Relays, which are immune to operation by D.C. The circuit employed is the Westinghouse

standard polarised circuit, which is free from interference by extraneous currents,

false feeds, or crosses in the circuits. The average time for the operation of a

pair of points is 2\ seconds.

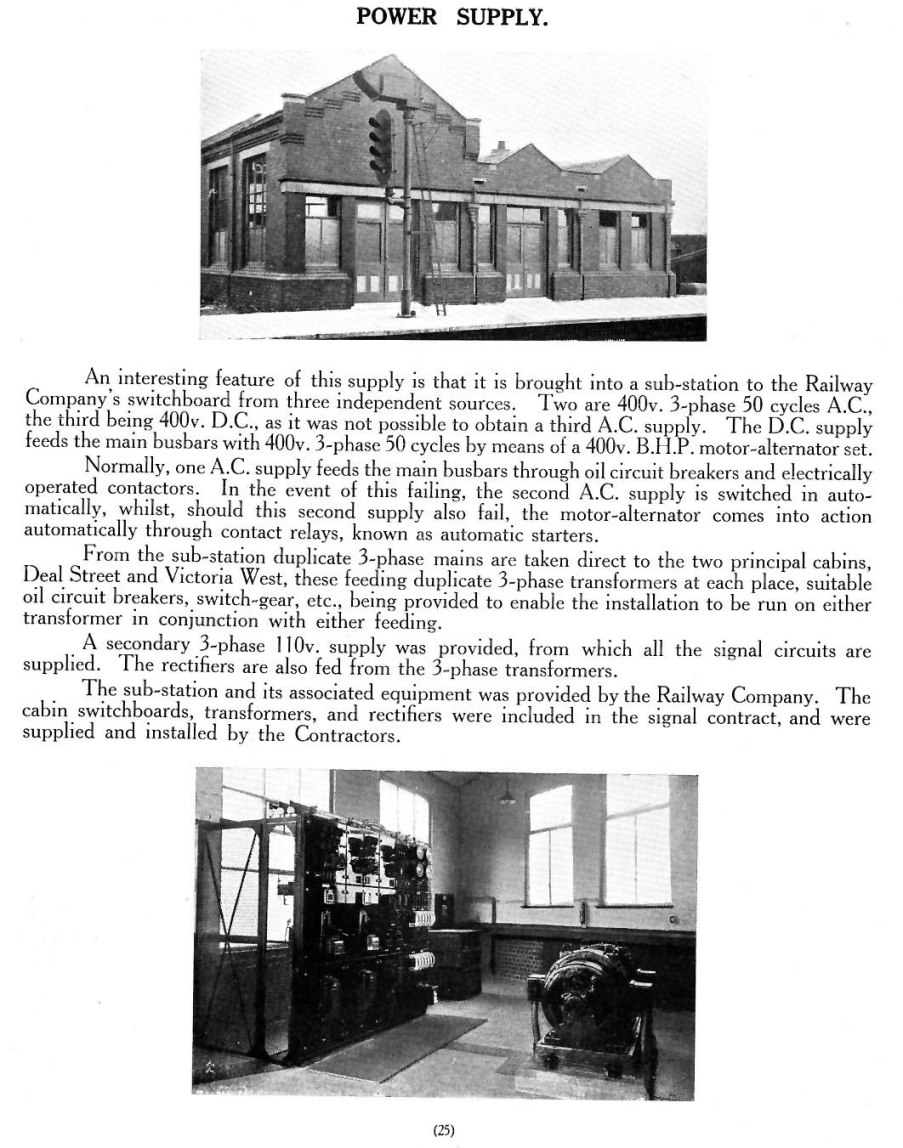

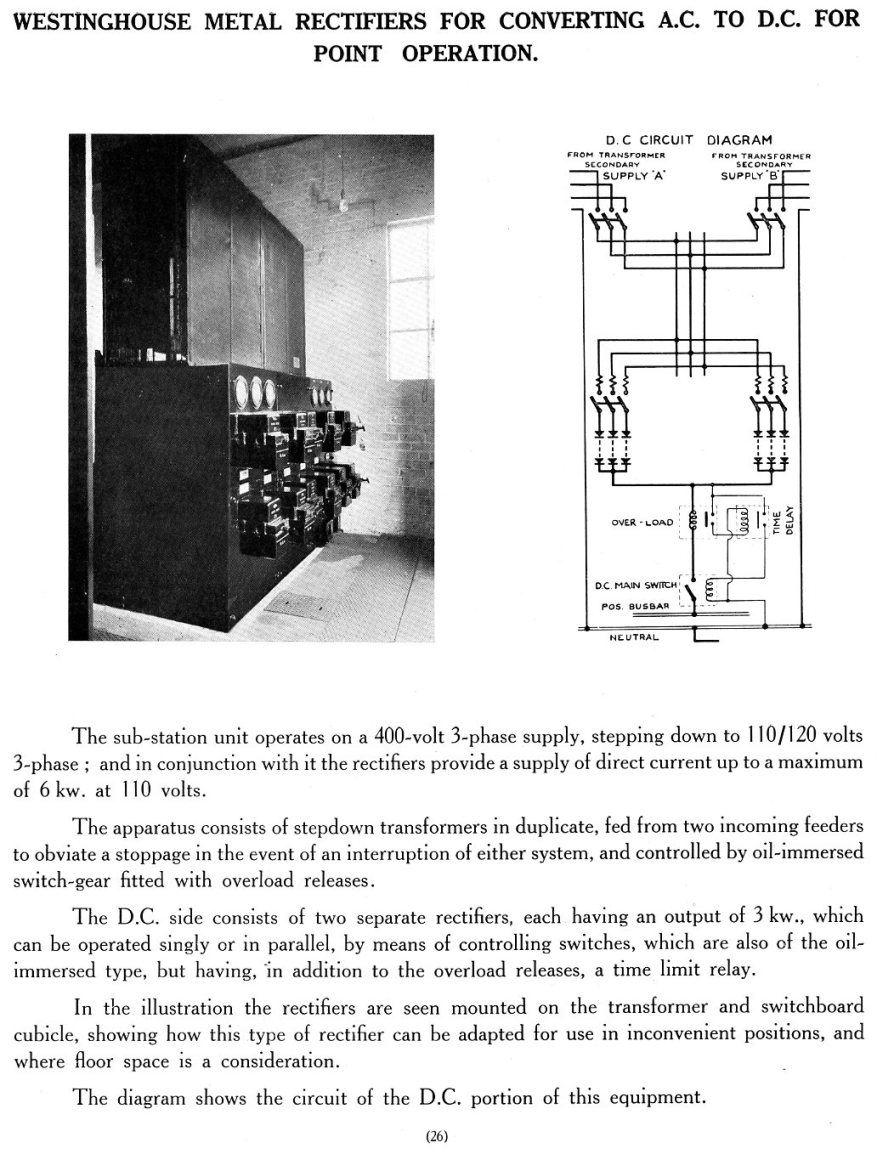

The point machines are operated by direct current, as this is more economical in an installation such as this arrangement. Hitherto, one of the disadvantages of D.C. operation has been the use of large batteries, which require expensive and complicated charging arrangements- By employing the Westinghouse Metal Rectifier, this disadvantage has been overcome at Manchester, the supply for the points being taken direct from the 3-phase supply mains through the rectifiers to the D.C. busbars. Duplicate rectifiers are provided, each having a capacity of 3 k.v.a. (see page 26), thus ensuring ample margin for the maximum number of point machines which can be thrown at one time.

The track-circuited area extends from Ordsall Lane and Salford to Victoria East, and required the installation of 179 track circuits. The track circuits are of the condenser-fed type, a condenser being connected direct in one leg of the feed circuits. The relays are of the double-element vane type. With very few exceptions, both track-feed transformers, condensers, and relays are housed in the cabins. The track-circuit cables are brought to terminals located at the ends of the relay racks, and the wiring from these terminals to the apparatus is carried out with wire insulated with "Maconite" and covered with a "flame-proof" braid. An examination of the photographs will show the neatness of the arrangements and of the wiring. This method of installation has considerable advantages, dispensing as it does with the many apparatus cases that would otherwise be required, while there is practically no need for a linesman to leave the cabin to adjust track circuits.

The signal control and point indication relays are also located in racks, with similar terminal and wiring arrangements. The relay racks are located in the lower sections of the cabins immediately below the interlocking frames. This arrangement reduces the wiring required to the minimum. The total number of relays of various types furnished for this installation was 826.

All the cable used on this contract, equivalent to 334 miles of conductor, was "Maconite" insulated, the dielectric thicknesses and tests being to British Engineering Standards Association Spec. No. 7 for 660-volt cables. Multi-core cables were used wherever possible, suitable size core cables being used for each individual function. In other words, separate cored cables were taken from the signal cabin to each piece of apparatus. This course is usual with modern installations, and obviates the great amount of terminating which is required when large multi-core cables are used, with disconnection boxes situated round the interlocking. For internal wiring, such as for cabins, single conductor cables were employed, covered overall with a flame-proof braiding.

Track diagram, Ordsall Lane and Salford area

Sidan uppdaterad den 5 juni 2008