Westinghouse Style K Powerframe in Malmö, Sweden

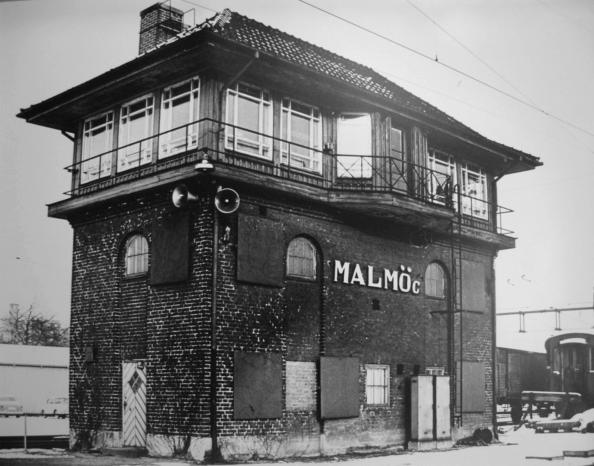

The Westinghouse Brake & Signal Co. Ltd. Style 'K' power frame at

Malmö Central was the only Westinghouse frame in Sweden, but it was

important as it pioneered the switch from german-style to british-influenced

signalling principles in Sweden. Only by taking this step was it possible

to control large stations from a single signal-box. It was also an incentive

to the swedish Signalbolaget (a subsidiary of the Ericsson telecom

company) to develop an electrically-locked frame.

Until 1925 Malmö Central Station was controlled from several mechanical

signalboxes. The station was rebuilt during the 1920s, and the State

Railways wanted to rationalise the signalling and control the whole layout

from a single box. This was only possible if shunting could take place on

signalled and locked routes. All previous interlockings in Sweden were of

german types, where trains run on locked routes, but shunting is regulated

by hand-signals. Track circuits were uncommon. At all but the smallest

stations several boxes where necessary to control the layout. These boxes

were under the control of a local controller (train director) using electrical

releases for the signal levers.

In british-style interlockings it is customary for shunting operations

to be directed by fixed signals on locked routes, so the State Railways

decided to buy a Style K frame from the british Westinghouse Brake &

Saxby Signal Co. The Swedish Signalbolaget (signalling subsidiary

of the Ericsson telecom company) acted as an intermediary.

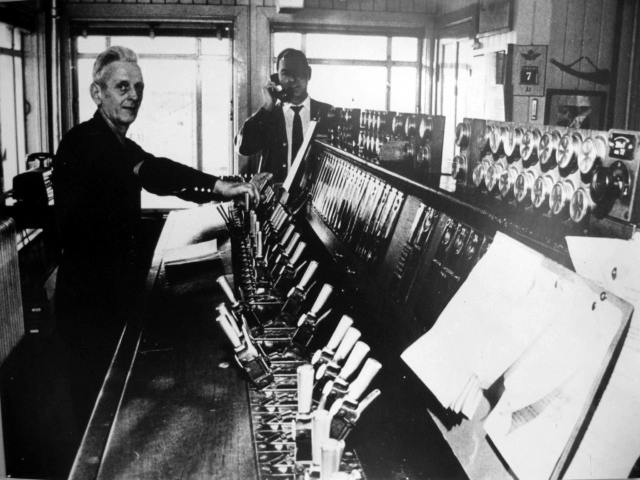

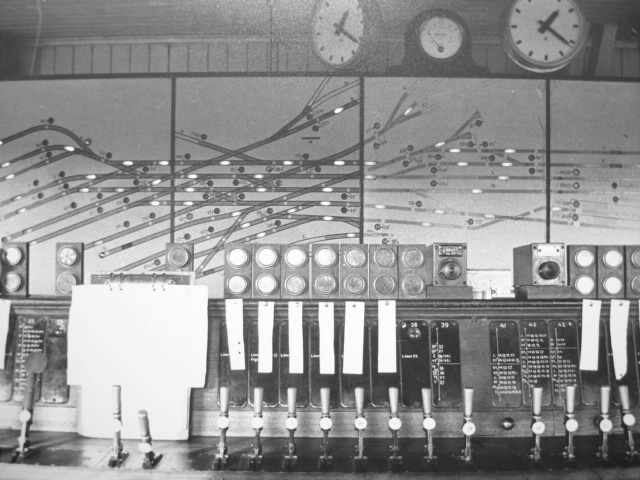

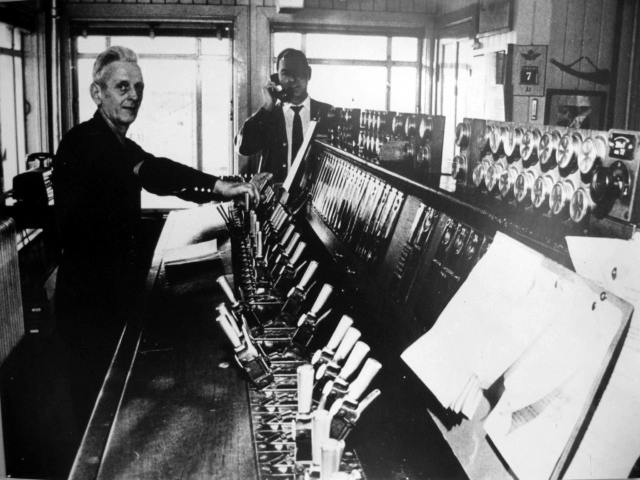

The powerbox was brought into use in 1925. The picture shows the box in

1965 [Göteborgs Landsarkiv]

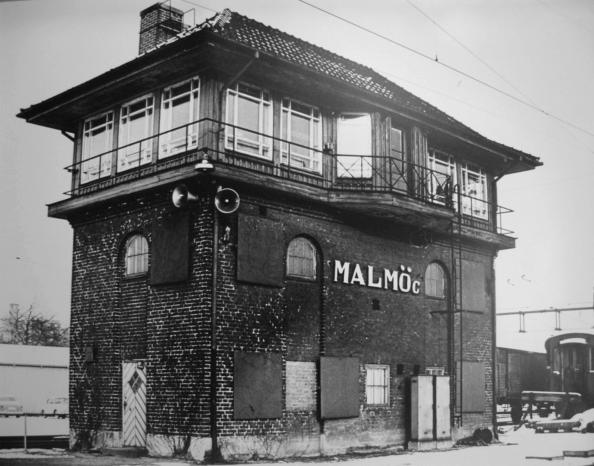

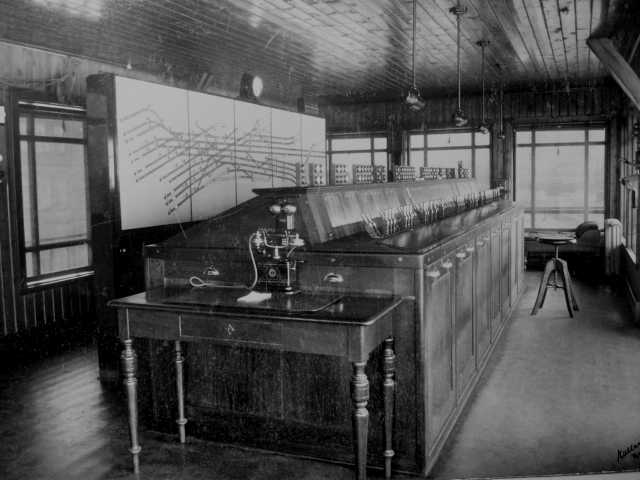

The picture above, from 1925 - 1933, shows the frame and the illuminated

diagram. [Swedish Railway Museum, picture number 6081].

The signal levers were of the push-pull-type. The lever could control two

routes, as the signalman could either push or pull the lever from the neutral

position. The annotation for the routes accordingly used the suffix

psh for push and

pll for pull.

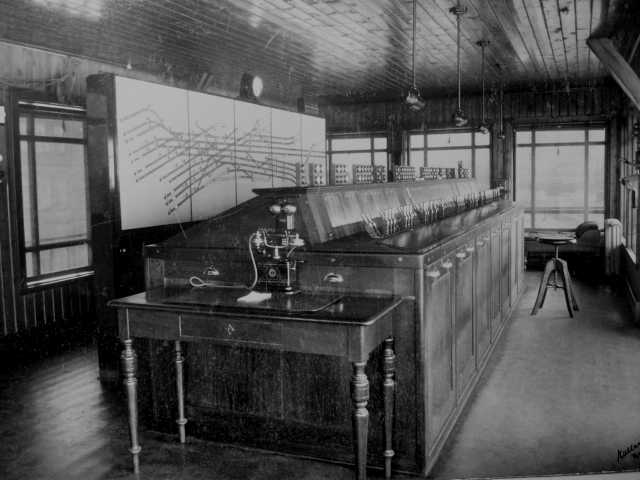

This picture, probably from the 1970s or 1980s, shows a variety of telecommunications

equipment. [Swedish Railway Museum, picture number 6082].

Technical description

This description is based on data in Banavdelningens berättelse

(State Railway infrastructure department's annual report)1925 pp 102

-

The frame was equipped with

- 33 signal levers for 14 starting signals, 5 home signals and 57 shunting

signals

- 41 levers for 63 switches and 3 derails (blocks)

A small installation compared to the style K frame

at London Bridge (311 levers)!

There were 57 track circuits. 77 main routes and 186 shunting routes could

be set up. The interlocking used 98 AC relays and 173 DC relays.

Power supply:

- Machines for switches and derails were furnished from

a storage battery in the signalbox. This battery was charged through a mercury

arc rectifier. A rotary convertor was available as a standby.

- DC relays were supplied from a 12 volt storage battery,

charged by a pendulum rectifier.

- A transformer with secondary windings for 55 and 110

volts supplied signals, track circuits and AC relays.

Signals

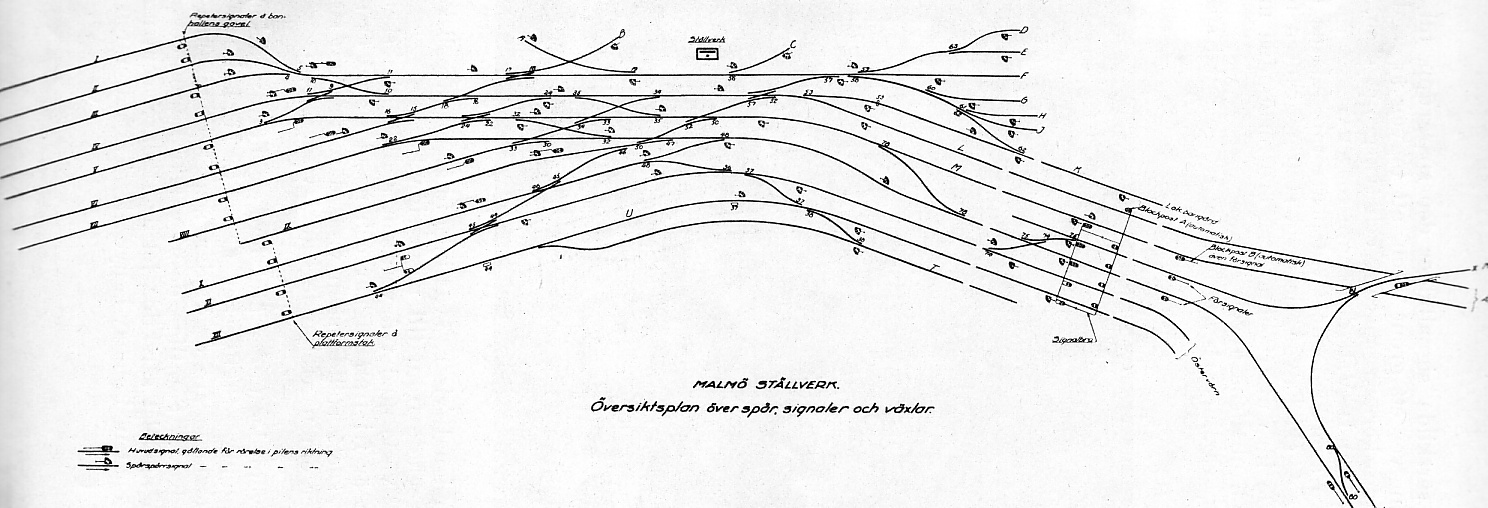

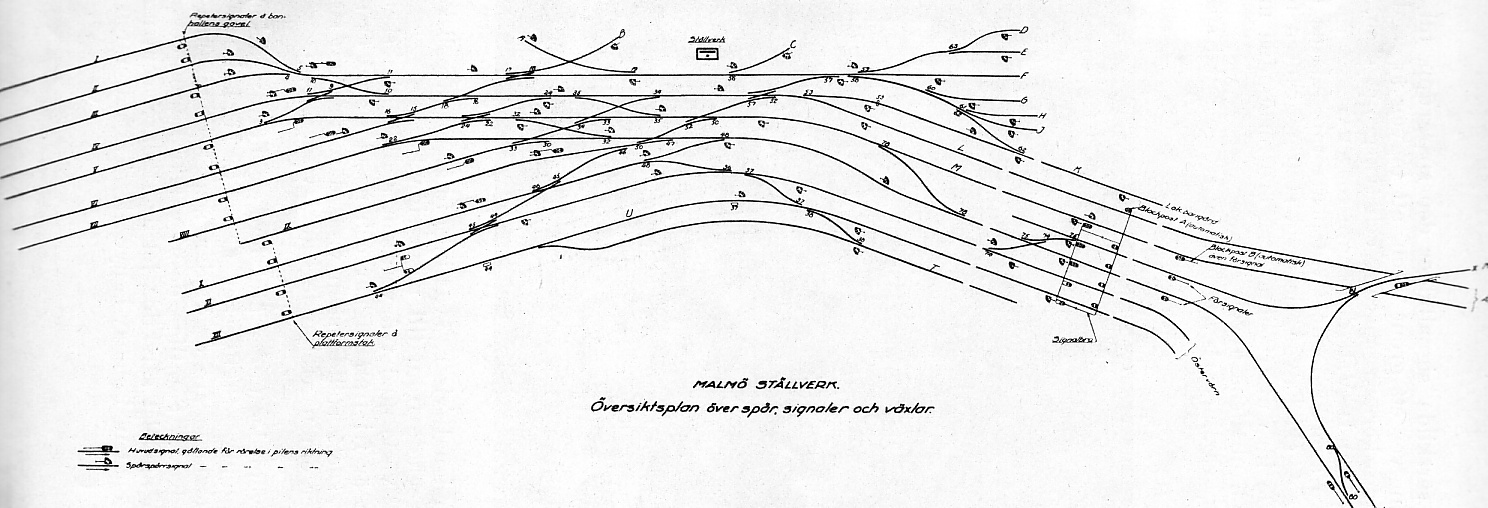

The diagram reproduced below is from Banavdelningens berättelse 1925,

page 105. The all-over roof covering the main platforms is near

the left edge. Platform tracks VIII to XII belong to the so called Local

Station, used by short-distance trains. The 'box is near the upper edge.

The double-tracked Southern Mainline to Stockholm leaves to the right.

Connecting tracks to the freight yard are brought over the mainline on a

viaduct. The two tracks disappearing near the lower right corner of

the diagram are the so called Contintental Line to Trelleborg and the track

to the State Railway's rolling stock works. Breaks in the track on

the diagram are used where the actual distance is considerably longer than

shown.

The home signals are fixed to a gantry (Signalbro) spanning most of the lines.

A single green light is shown for routes to the short tracks of the Local

Station. Routes to the longer platform tracks number I - VII are signalled

by two green lights. This was contrary to later practice.

Inner starting signals could be found near the ends of most platforms.

These signals co-acted with repeater signals on the outer edge of the all-over

roof. Outer starting signals were mounted on the same gantry as the home

signals.

Shunting routes where signalled by position-light dwarf signals.

"Blockpost A" and "Blockpost B" are automatic block signals

for the Southern Mainline. Automatic block was necessary as, due to

the distance, the signalmen could not observe the tail lights of all

trains.

This picture, from february 1980, shows some of the inner starting signals

and a few position-light dwarf signals. The Southern Mainline was

only electrified during the 1930s, so no overhead line portals were available

for mounting the signals when the power interlocking was built.

The coach visible behind the locomotive of the departing train is a sleeper

bound for Moscow via Trelleborg - Berlin.

The Malmö interlocking used main signals as inner starting signals

(intermediate signals in current swedish terminology). This use of main signals

was standard practice in earlier mechanical and power interlockings. However,

most power interlockings built subsequently used only dwarfs as inner

starters. These dwarfs can show a green aspect to indicate that a main route

has been set up. Shunting routes are always indicated by lunar-white lights

only. Nowadays, as a safeguard against trains passing signals at danger,

dwarf signals for main routes display a red aspect at all times except when

a main route has been set up.

Levers and Indicators

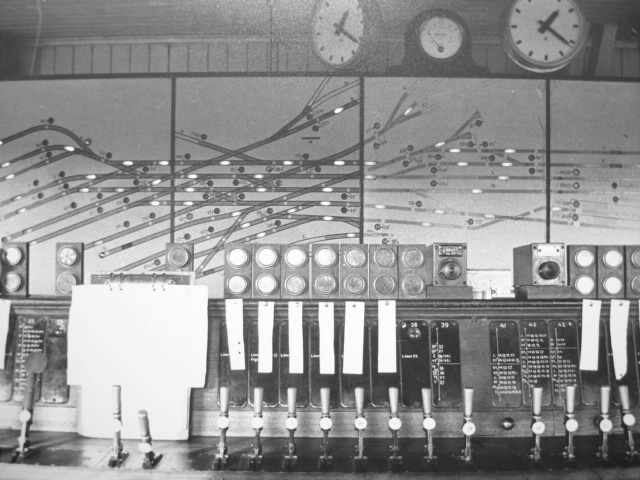

Above each lever can be seen a plate with the number of the lever

and, in the case of a signal lever, a list of other levers which are

required for the route. Signal indications are repeated on the illuminated

diagram. Free track circuits are indicated by a white light. Originally,

contrary to later practice, the track circuit lights where normally extinguished,

and lit up to indicate occupation of the track circuit. Switch position

indicators can be seen immediately above the switch levers. These indicators

were also known as windmills. Above some of the signal levers are time releases

used for instance if it is necessary to cancel a main route after the signal

has been taken off. Picture No 6086, Swedish Railway Museum.

This picture was probably shot after 1956 - the clocks on both sides of the

ammeter are non-existant on the picture taken in 1956.

A picture from 1963 [via SJ fotoklubb, now in Göteborgs Landsarkiv]

This picture is probably from 1965, and was reproduced by the Malmö

Railwaymen's Photo Club.

Illuminated diagram and controls and indications for the power supply.

[SJ fotoklubb Malmö, Göteborgs Landsarkiv]

|

Left: Enlargement of part of a picture from

the swedish Railway Museum. A lever collar has been placed

on one of the levers so that it can not be thrown by the signalmen

Right: A few pieces from the

frame have been preserved at the infrastructure authority's museum at Ängelholm.

The indicators are not in the same

position as on the real frame. The small box in the upper right corner is

for emergency release of a main route. This arrangement was replaced

by time releases at an unknown date [2005]

|

|

Local control. Safety and Reliability.

At interlockings built prior to the Malmö

powerbox, the work of the signalmen was controlled by a local controller

(train director, sw

tågklarerare)

using electrical releases. This was neccessary to coordinate the boxes,

and as a safety measure due to the lack of track circuits. In

the Malmö powerbox, locking and track circuits made it possible

for the signalmen to operate the interlocking plant with complete safety

without releases from the controller. The local controller's office,

near track VII, had a simplified illuminated diagram to show track occupancy

on some platform tracks, but no releases for the signals. The

local controller gave the

right away

handsignal to departing trains, but the signalmen mainly managed the

train and shunting movements on their own. This partition of work

was applied also to most later large powerframes in Sweden.

A few weeks after the interlocking had been brought into use, the

last car of an arriving train was derailed and overturned when

a switch

was thrown under the train. A guard was killed and some passengers were injured.

The cause of the accident was a faulty part in the locking frame. Otherwise,

the interlocking plant seems to have functioned well.

Relock or Replace the Powerframe?

In the middle of the 1950s, it was time again

for rebuilding Malmö Central station. The State Railways 3d district

launched the idea that the powerframe ought to be replaced by a relay

interlocking. Slackness had developed in the locking. As this was the only

British-style frame in Sweden, it was thought that maintenance could be

simplified if it was substituted by standard equipment. In a perhaps somewhat

exaggerated report, the district stated that the interlocking would have

to be taken out of use for six months if it was decided to relock and extend

the Styel K frame. During these six months hand signalling was to be used.

On the 19th September 1956 Westinghouse Brake &Signal Company

offered

- equipment for extending the interlocking due to the yard rebuilding,

£ 640

- a complete set of spare parts for the mechanical locking, £

3 525. There was also an option of renewing only parts of the locking.

Delivery would be possible 9 - 15 months after the order was placed. The

installation of the new equipment could be carried out by four locking fitters

during a 12 hours posession after preparatory work during several nights.

Alternatively, four locking fitters could accomplish the entire relocking

and extension during three weeks with disconnected locking and handsignalling.

Westinghouse mentioned that they considered the locking fitters of

the State Railways to be thoroughly conversant with the locking of the Style

K frame, and capable of carrying out the relocking and extension.

The state railways decided to relock and life-extend the powerframe. This

decision was probably influenced by a lack of suitable swedish relay interlocking

technology for large installations.

I have not as yet managed to get information on how the relocking was carried

out and how long handsignalling had to be used.

A

Above: Probably a picture

from the final decade of the box. At the window can be seen equipment

possibly used to control a switch machine which for some reason was not

on the frame

. [Swedish Railway Museum,

Picture No.6080]

Below; Picture in Göteborgs Landsarkiv, via SJ fotoklubb Malmö

The Style K frame was the most technically advanced frame with

mechanical locking in Sweden. It was also the last really big swedish

powerframe with mechanical interlocking. In 1926 or 1927 the first electrically

interlocked frame was brought into use at Hässleholm. This development

was parallell to Westinghouse's development of the Style L frame

. The Style K frame in Malmö was

replaced by a computer based interlocking in 1982

.

Sources

Documents from the State Railways in Riksarkivet (public record office)

Banavdelningens berättelse 1925

Pictures in the archive of the Swedish Railway Museum, Gävle,

and Göteborgs Landsarkiv.

Swedish Version

Home

Last updated 4 Februari 2006